An ISO 9001:2008 certified manufacturer

Quality Overview

- We follow the ISO 9001:2008 QA system.

- We follow the ISO 9001:2008 QA system.- Quality begins right from the raw material stage. All raw materials are purchased directly by the Directors who have more than 4 decades of experience in procurement of raw materials from the right sources.

- RM is handled by a highly experienced team who sort and grade the raw materials with expert hands according to various parameters laid down in the order.

- Various samples of the blends are tested for the correct composition prior to spinning.

- All machines are properly cleaned to avoid any contamination of previous blend prior to next blend starting the production process.

- Overall cleanliness of the plant is also enforced to ensure a clean, healthy working environment apart from ensuring that no fly away contaminant enters your blend.

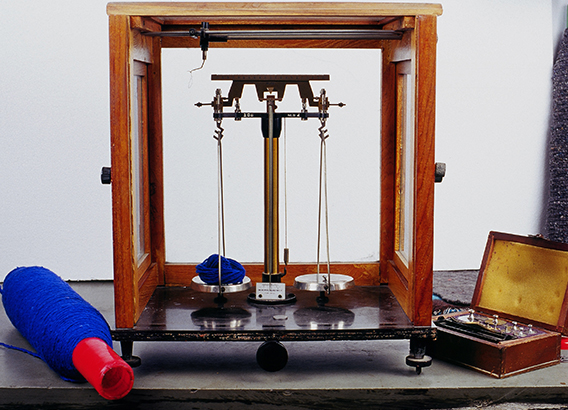

- Carding Count of the yarn is tested every 15mins to check for any variations in the yarn count. If any inconsistency is found the card is immediately stopped and readjusted for count.

- Spinning count of the yarn is tested every 30 mins to check for any variations in the yarn count. If any inconsistency is found the spinning machine is immediately stopped and readjusted for count.

- Every 2 hours an independent QA inspector draws samples from the blend, card and spinning machine to check for composition, count, twist & strength to ensure that the floor level engineers findings are consistent with QA findings. This QA inspector is not reporting to the production team but rather directly to the management with their findings.

- Every 2 hours an independent QA inspector draws samples from the blend, card and spinning machine to check for composition, count, twist & strength to ensure that the floor level engineers findings are consistent with QA findings. This QA inspector is not reporting to the production team but rather directly to the management with their findings.- During weaving every unprocessed roll is measured for length and weight in order to check for proper weights. Rolls are also randomly checked for compliance of construction parameters.

- Prior to processing each roll is visually inspected to see for any defects and such defects are either repaired if possible of marked to ensure that they do not get packed in your consignments.

- Post processing each roll is again visually inspected for any defects and such defects are either repaired if possible of marked to ensure that they do not get packed in your consignments.

- Records of all testing and checks are maintained in our records for a period of not less than 2 years to refer back to in case of any difference in findings between clients end and our end.

- Post finishing of the final blanket/throw each piece is again weighed and inspected whilst packing to make sure there are no defects. Only “Zero” defect goods are packed in your consignments.

- A proper preventive & breakdown maintenance schedule is followed to ensure that the machines are running properly and no inconsistency creeps into the product due to ill-maintained machines.